Plastic extrusions, sometimes referred to as plastic profiles or sections, are used widely and across a range of sectors including construction, manufacturing, transport, retail and events. However little is known about what a plastic extrusion actually is or how it's made.

In broad terms, extrusion implies a pushing out action. In this context it refers to the process of that is involved in creating the plastic tube, angle or edge trim through combining raw plastic with a die through a melting process in order to achieve the desired shape.

What is the extrusion process?

The process behind a plastic extrusion can be broken down into three steps.

- Mixing

- Melting and extrusion

- Shaping and cooling

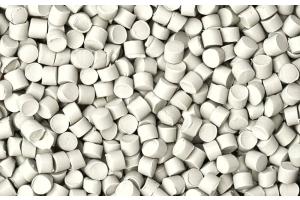

Stage 1: Mixing

The first step is to mix all raw ingredients for a plastic extrusion. Raw plastic, typically in the form of compound, is first fed into a long barrel-shaped extruder. At this stage, any additives for the plastic extrusion, such as colourants, can be added according to the required specifications.

Stage 2: Melting and Extrusion

The second step of plastic extrusion is to melt the ingredients together. Along the barrel there are heating zones strategically positioned to melt the plastic material gradually, reducing the risk of overheating and degrading the polymer. Further heat is then generated through friction from a rotating screw. The molten plastic emerges at the end of the barrel and is subject to filtration to ensure that no contaminants are present in the final product. After this the plastic extrusion will take its final shape (last stage)

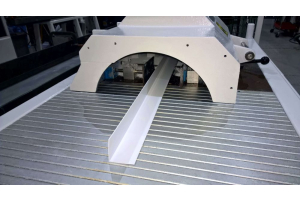

Stage 3: Shaping and Cooling

The last step of plastic extrusion is shaping and cooling. The molten polymer is then forced into a die, which attributes the final shape of a plastic extrusion. However the process continues as it is continually moving and the profile is held in shape by formers and normally goes through water baths as part of the cooling process. The profile then hardens upon cooling. Now the plastic extrusion is completed.

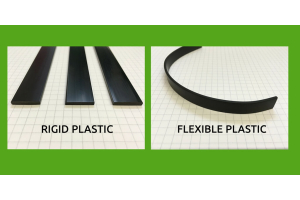

Examples of plastic plastic extrusions

Plastic extrusions can take many forms and we sell a huge range in our safe, secure online shop. Our plastic extrusions include plastic angles, plastic channels, edging and flat strips, a variety of plastic H and T Sections, as well as many more.

We also specialise in custom plastic extrusions for more specific requirements. To find out more, see our custom plastic extrusions section or speak to one of our experts by calling 01208 873566. Our advisers are available any time Mon-Fri, 9am-5pm.