Available Mon-Fri, 9am - 5pm

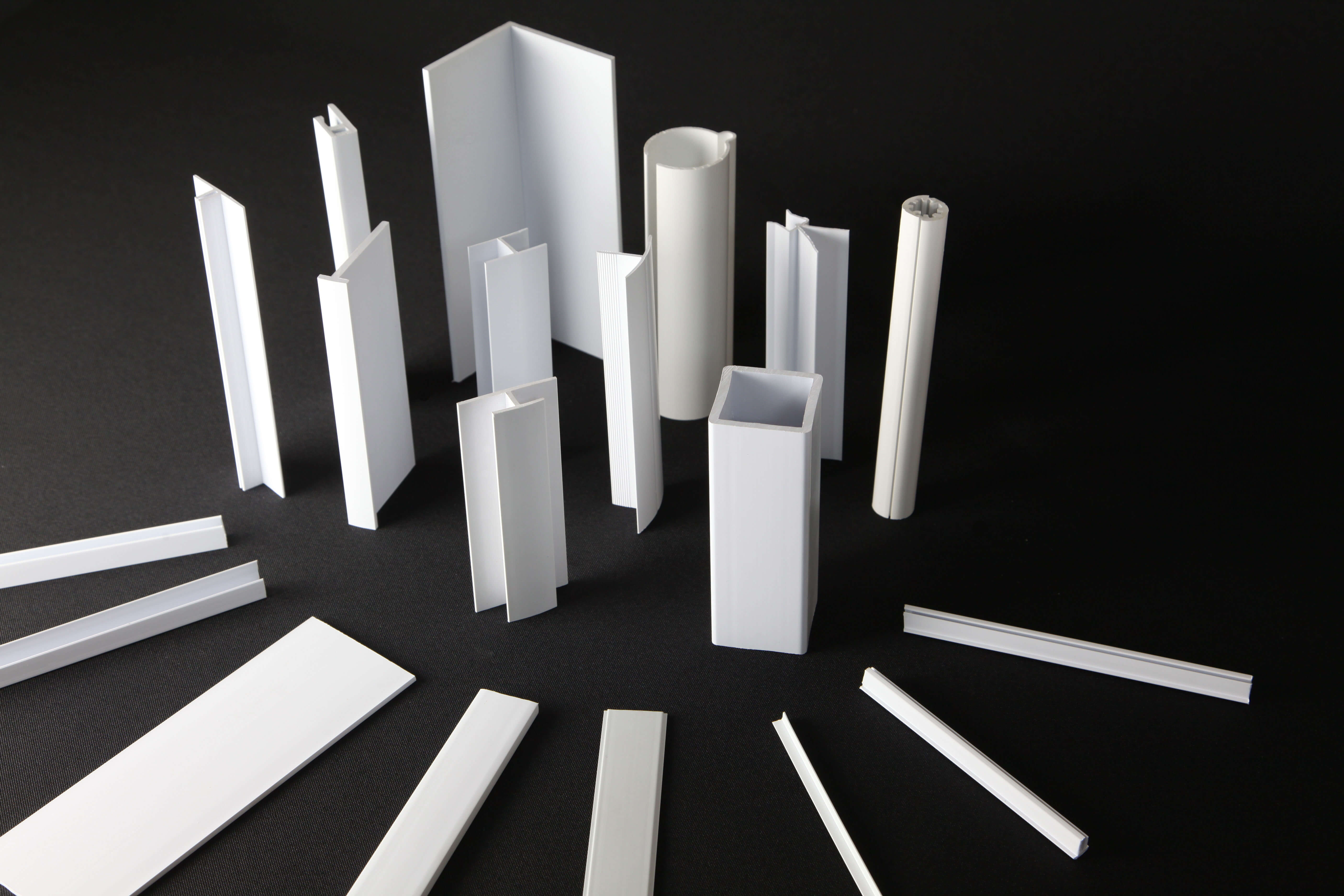

Polyvinyl chloride or PVC plastic is one of the most used plastics in the world. It is incredibly versatile and found in an endless array of products that impact our everyday lives, and is suitable for recycling. PVC is particularly used for building and construction but also plays an important role in health, transport, packaging as well as art and fashion.

Rigid and flexible PVC plastic

PVC plastic comes in two main forms: rigid and flexible. At MKM Extrusions, we use both but if you're unsure on which you need for your project, consult our handy guide. To attribute it a flexible nature, plasticisers are added to PVC. In this way, the 'u' in 'uPVC' stands for unplasticised and uPVC plastic retains rigidity.

Unplasticised polyvinyl chloride (uPVC plastic)

Rigid uPVC is often used externally as it is more resistant to weathering and isn't susceptible to biological decomposition. In addition, it retains its shape at normal temperatures, though it can be reshaped under intense heat. It features prominently in construction, particularly in windows. All PVC is stabilised, however in the double glazing and windows industries, additional stabilisers are often added to the uPVC, which are not used in our uPVC products. Another difference is the K value, which varies for different applications. K value is a measure of the degree of polymerisation, or the molecular weight of the polymer chain. The K value for double glazing and window applications is higher than for profile extrusions, whereas the K factor for moulding applications is lower than for profile extrusions.

uPVC can also be used internally. For example, it provides a durable edge protection to boards, panels and other applications.

Flexible polyvinyl chloride (flexible PVC plastic)

Flexible plasticised polyvinyl chloride is durable and used for a number of internal applications. Our flexible profiles are often used for applications such as edge protection and cover strips for boards, panels, furniture and worktops amongst others.

We use both types in our profiles

In a number of products on our secure plastic extrusions shop, you can choose between flexible or rigid plastic dependent on your needs and whether you require something for external or internal use. Our manufacturing processes are ISO 9001:2015 and ISO 14001:2015 accredited, which means a quality product is assured with environmental considerations being at the heart of everything we do.

If you require something bespoke or wish to find out more about our products and custom plastic extrusion services, call us on 01208 873566. We are available Monday-Friday, 9am-5pm. You can also email us at info@mkmplastics.com. We look forward to hearing from you.