In August of this year we had a double celebration as we were successful in upgrading our quality and environmental accreditation to ISO 9001:2015 and ISO 14001:2015. We have been accredited with both standards for many years: ISO 9001 since 2001 and ISO 14001 since 2002.

Although we are well used to meeting the requirements this year was a particular challenge for us because both standards were revised in September 2015 in a major way. We are particularly pleased with this achievement as we tackled the new requirements of the standards completely in-house.

Having been audited in August 2015 we did not need to meet the new standards for another three years. However, as we always like to keep ahead, we decided to go for re-certification to the new requirements this year.

What are ISO 9001 and 14001?

ISO 9001 is the internationally recognised standard for Quality Management Systems (QMS) and is the most widely used QMS standard in the world. It provides the basis for effective processes and people so we can deliver quality product and service consistently. Managing quality is a key priority for our business.

ISO 14001 is the internationally recognised standard for Environmental Management systems (EMS) and is the most widely used EMS in the world. It helps us control our environmental aspects, reduces our environmental impacts and ensures legal compliance. Managing our impact on the environment is a key priority for our business.

At MKM Extrusions we like to streamline our processes so we use a combined system which is our Quality and Environmental Management System (QEMS). The QEMS is externally audited annually and is re-certified every three years.

We are committed to following ISO 9001 and 14001 standards

Demonstrating commitment to continual improvement is a key requirement and what we always strive for which is reflected in our mission statement.

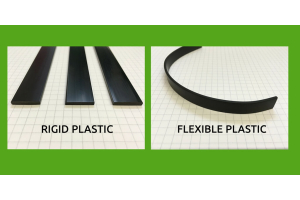

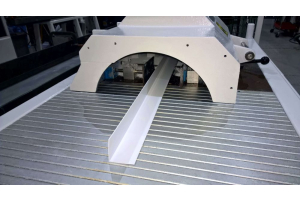

At MKM Extrusions, we have a set of principles guiding our production quality. This standardised approach ensures we consistently manage our activities so our customers receive quality products that meet their requirements. We provide a product that is fit for the intended purpose and which is delivered without deviation from the quality specification agreed.

We recognise that our activities have an impact on the environment so we work towards the protection, conserving and enhancing of all aspects of the environment over which we have control.

We take environmental performance very seriously, and have taken steps to improve so we can control our impact on the environment. We are especially committed to preventing pollution. See our blog on PVC profiles and the environment to read more about the effects of plastic extrusions.

For more information about our quality and environmental management systems or our PVC profiles, please feel free to get in touch. Call us on 01208 873566 or email info@mkmplastics.com