You may not realise but plastic extruders play a fundamental role in many sectors, including construction, manufacturing, refurbishment, interior design and fit out. But what is a plastic extruder?

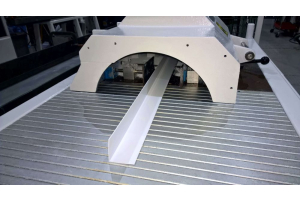

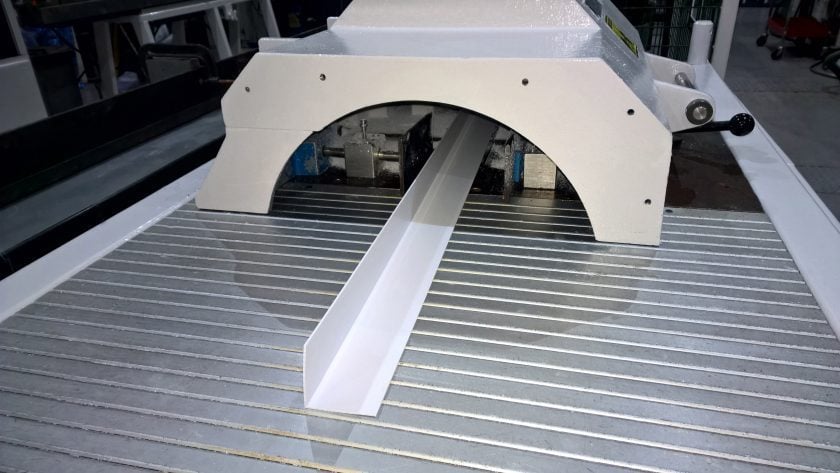

In simple terms, an extruder is a device that creates extrusions by pushing or pulling a material through a shaped die in order to form a continuous length with a preset cross section.

A standard machine consists of the barrel containing the screws and raw material, and screws to force and combine the material within the barrel. Different variants of this core concept apply to across a range of industries working with different materials.

An Extruder Machine

Types of Extruder

There are several different types of extruder. If you've ever seen pasta being made, you’ll have witnessed one in action. Play-Doh machines for children are also good examples of extruders. The term can also refer to the person operating the apparatus, but here we'll focus on the device itself.

Extruders can be categorised by wet and dry, as well as low, medium and high shear. Plastic extruders are categorised as dry which means that the temperature is increased using the materials only.

Shear, literally meaning the action of two parts moving in opposing directions, describes the type of processing that the machine executes. Low shear is for plastics and pastas.

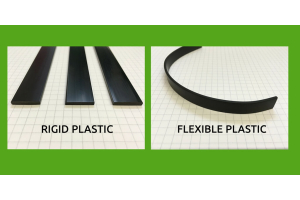

Our Extruded Profiles

We have over thirty years' experience in producing extrusions of the highest quality, but don't take our word for it; you can sample the handiwork of our extruders at our secure online shop. They come in a variety of shapes and sizes: from angles and edge lipping to channels and flat strips. We also produce custom extrusions for large or bespoke orders. Just call and we can talk you through our process.