In this blog we will introduce you to the meaning of the term uPVC, the benefits of using it, the type of uPVC we use to manufacture rigid plastic extrusions, the type of uPVC which is used for other types of products, and how PVC is made flexible.

Introduction to uPVC

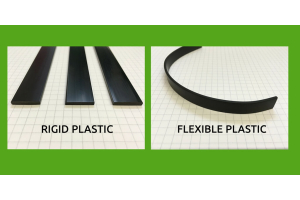

The term uPVC is an abbreviation for the full phrase which is ‘Unplasticised Polyvinyl Chloride.’ The 'u' in 'uPVC' stands for unplasticised which means it does not have added plasticisers and so it retains rigidity. It can be described as being rigid (like a ruler) rather than flexible (like a belt).

This type of plastic material has advantages over alternatives such as wood or aluminium. Some benefits of using uPVC include:

- Low maintenance

- Longer lasting

- Can often be used outside as well as inside

- Energy efficient

- Recyclable

- Easy to clean

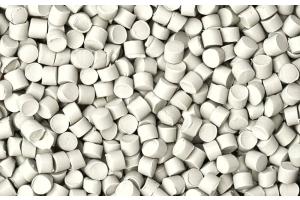

uPVC is supplied to manufacturers as compound, which looks like small round pellets which you can see in the above image. When processing these pellets care should be taken to minimise spills and to clear them up promptly on occasions when spillages occur.

Many sectors use uPVC widely including extrusions, mouldings, double glazing, windows, doors, plumbing, drainage and building materials.

The type of uPVC used to manufacture rigid plastic extrusions

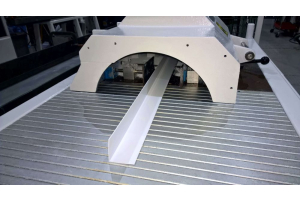

uPVC is often used in the manufacture of plastic profiles. All uPVC is stabilised, and here at MKM Extrusions we use an external grade of uPVC which makes our rigid extruded profiles suitable for outdoor applications.

We offer rigid uPVC profiles which are listed on our online shop in two colours: white and black. If other colours are required this can be done as custom manufacturing for larger production runs.

The type of uPVC used by some other industries

The type of uPVC used in industries such as windows and double glazing is slightly different to the material we use, whereby additional stabilisers are often added. These stabilisers may be needed due to the purpose of the product.

Another aspect that is different for windows and double glazing is the K value. This is a measure of the degree of polymerisation, or the molecular weight of the polymer chain. The K value varies across different applications. The K value for double glazing and window applications is higher than for profile extrusions, whereas the K factor for moulding applications is lower than for profile extrusions.

What type of material is used to make flexible plastic extrusions?

When manufacturing flexible plastic profiles here at MKM Extrusions, we use a different type of raw material than when we make rigid profiles. To make the plastic flexible, plasticisers have been added to the PVC. So our flexible extrusions are made from PVC and not uPVC, the relevance of the ‘u’ meaning unplasticised. Our flexible PVC profiles are suitable for indoor use.

Our rigid uPVC is rigid like a ruler, although depending on the profile it may flex over a 3 metre length. Whereas our flexible PVC profiles are softer, you could put it around your waist like a belt.

Some other examples of products which can be made from flexible PVC by other manufacturers are wire casings, hose, gaskets, seals and straps.

You can read more about this in our blog explaining about the difference between uPVC and PVC.