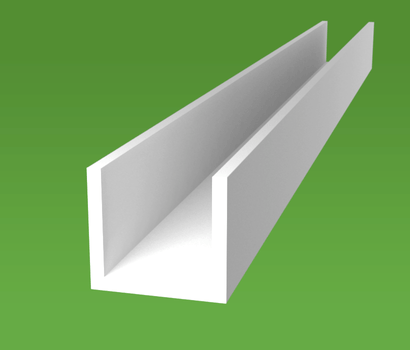

Description guide for Plastic Channels: 1st internal width - 2nd internal height - 3rd thickness | M = metres, mm = millimetres

Plastic U channels can be used for capping, sliding track and edging trim for boards and panels. Plastic channel trim can cover unsightly and uneven edges giving a smooth and neat finish. The PVC channels are manufactured in the UK from external grade rigid PVC. Plastic channel is available in black and white.